Industries

Services

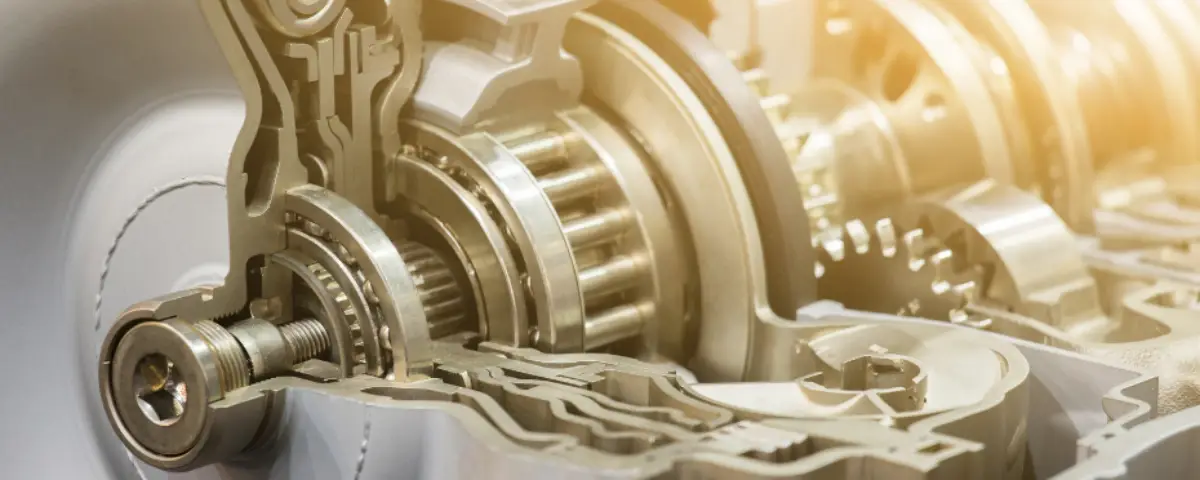

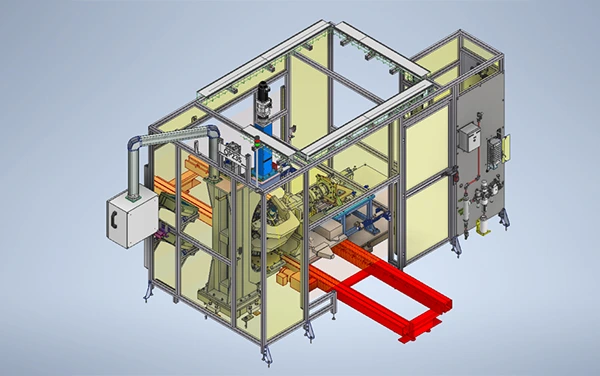

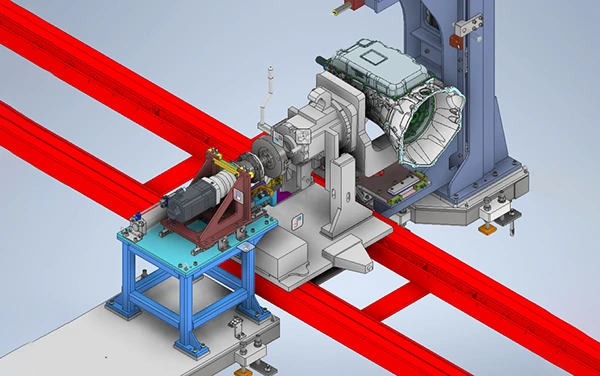

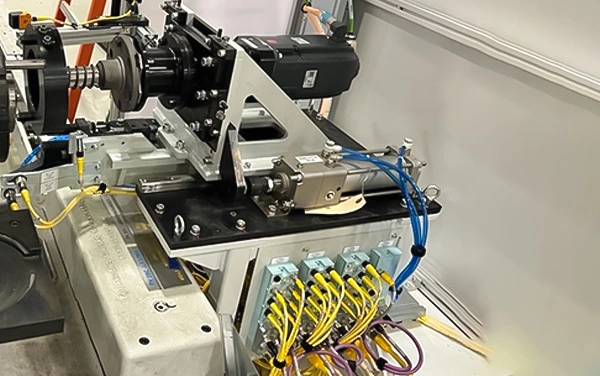

Engineering Services

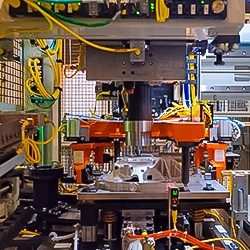

Manufacturing Services

Civil Engineering

Custom Manufacturing and Engineering Services

Resources