Industries

Services

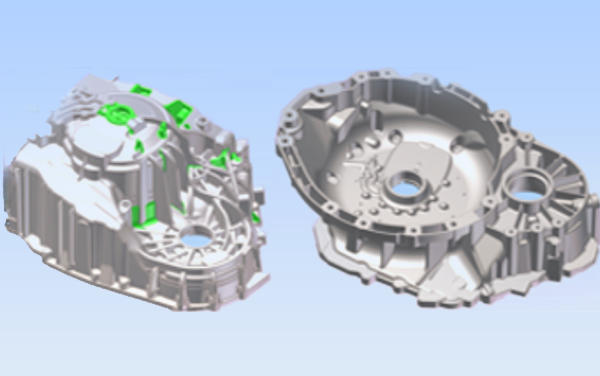

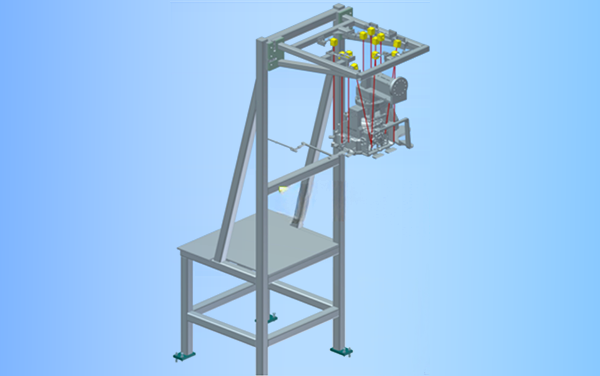

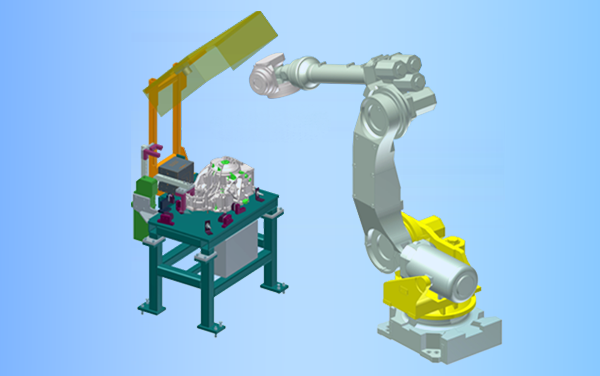

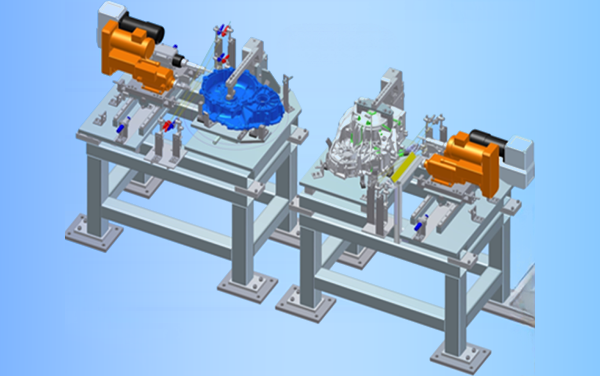

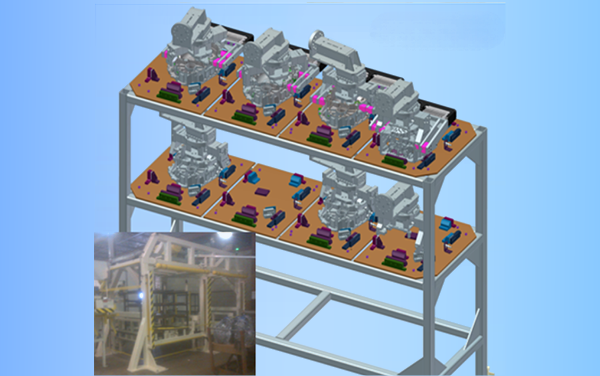

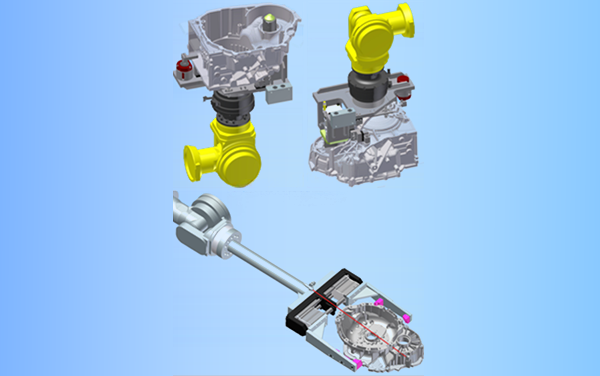

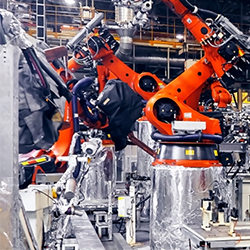

Engineering Services

Manufacturing Services

Civil Engineering

Custom Manufacturing and Engineering Services

Resources